At SuperVIG, we are dedicated to developing materials that drive sustainability in modern construction and appliance design. Our high performance vacuum glazing technology stands at the forefront of innovation, providing exceptional thermal insulation that significantly reduces energy consumption. With growing global awareness of environmental challenges, Vacuum Insulation Glass from SuperVIG offers a reliable and efficient solution to lower carbon footprints while enhancing comfort in both residential and commercial settings.

Innovative Technology Ensuring Longevity and Efficiency

The foundation of our product’s performance lies in our proprietary alloy solder combined with advanced low-temperature reactive welding technology. This precise process ensures a perfect bond between the glass layers, resulting in a vacuum leak rate as low as 10⁻¹² mbar·L/s. This ultra-low leak rate guarantees the durability and integrity of the vacuum environment for an expected lifespan of 25 years. Such longevity ensures that buildings and appliances fitted with our high performance vacuum glazing maintain superior insulation without degradation over time.

Our Vacuum Insulation Glass boasts an impressively low thermal transmittance coefficient of 0.42 W/m²·K, a key factor in reducing heat transfer through windows or appliance panels. This efficiency helps reduce heating and cooling loads, directly translating into lower energy bills and decreased greenhouse gas emissions. Furthermore, the slim profile of our glass allows for expansive window designs without compromising insulation, promoting natural daylighting and reducing reliance on artificial lighting.

Advancing Energy Efficiency Beyond Buildings

While our technology is a game-changer in the architectural field, it also plays an important role in home appliance innovation. Incorporating SuperVIG’s Vacuum Insulation Glass into refrigerators, ovens, and other appliances improves their thermal retention capabilities. Manufacturers can thus offer products that consume less electricity without increasing their size or weight. This enhancement aligns with the increasing consumer demand for energy-saving appliances that contribute to sustainable living practices.

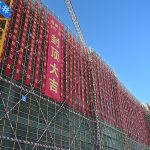

Our focus on continuous research and development ensures that SuperVIG remains a key partner for companies striving for environmental responsibility. We collaborate closely with architects, builders, and appliance manufacturers to customize Vacuum Insulation Glass solutions suited to varied climate conditions and application needs. This collaborative approach allows us to effectively support global efforts in reducing energy consumption and improving overall sustainability.

Conclusion

In conclusion, SuperVIG’s high performance vacuum glazing represents a significant advancement in energy-efficient materials. Our Vacuum Insulation Glass combines superior thermal insulation, long-lasting vacuum stability, and design flexibility, making it an essential component in sustainable construction and appliance manufacturing. We are proud to support our customers in meeting their energy-saving goals while contributing to a healthier environment. Together, with SuperVIG, we can create buildings and products that meet today’s needs without compromising the future.