At SuperVIG, we constantly push the boundaries of glass technology to deliver innovative solutions that meet the evolving demands of the building and home appliance markets. Our commitment to quality and reliability has made us a pioneer in vacuum insulated glazing, offering products that combine advanced materials and proprietary technology for superior thermal performance.

The Science Behind Double Glazed Windows Vacuum Technology

Our unique approach to double glazed windows vacuum leverages years of dedicated research and a portfolio of over 118 patents. We developed a proprietary alloy solder combined with specialized welding techniques that enable us to bond glass components at low temperatures. This process significantly enhances the sealing integrity of our glass units, controlling vacuum leak rates to an incredibly low level of ≤10^(-12) mbar·L/s. Such precision ensures long-term durability and performance, setting us apart in the vacuum glass industry.

Advantages of SuperVIG Vacuum Glass Solutions

We take pride in our technology’s ability to deliver a very low heat transfer coefficient, with values as low as 0.42 W/㎡·K. This translates into excellent insulation properties that help reduce energy consumption for heating and cooling in buildings. Additionally, our vacuum insulated glazing incorporates a high-efficiency getter that actively maintains the vacuum state inside the glass unit for an expected service life of up to 25 years. These features offer end users a trustworthy and cost-effective option to improve energy efficiency without compromising aesthetics or durability.

Meeting Modern Demands with Reliable Innovation

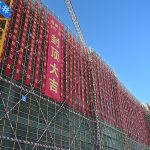

As market expectations evolve towards sustainability and smarter buildings, SuperVIG’s vacuum insulated glazing provides a compelling solution that aligns with green building standards and energy regulations worldwide. By integrating cutting-edge materials and engineering expertise, we enable architects, builders, and appliance manufacturers to achieve superior thermal insulation and soundproofing without adding bulk or weight. Our double glazed windows vacuum systems thus contribute to both environmental goals and enhanced occupant comfort. Moreover, these advanced glazing solutions help reduce the overall carbon footprint of buildings by minimizing energy consumption for heating and cooling. This not only supports compliance with increasingly stringent environmental regulations but also offers long-term cost savings for building owners. By combining innovation with sustainability, SuperVIG ensures that our vacuum insulated glazing products remain at the forefront of modern construction and design trends.

Conclusion

We at SuperVIG are proud to lead the way in advancing vacuum insulated glazing technology. Our commitment to continuous innovation and quality assurance ensures our products meet the rigorous needs of modern construction and appliance applications. By choosing our vacuum glass solutions, customers benefit from reliable, long-lasting performance that supports energy conservation and sustainable development goals.